Add to Cart

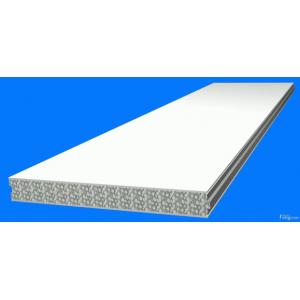

EPS Sandwich Panel Wall Fiber Cement Board New Building Materials Calcium Silicate

Introduction of sandwich panels

1. Introduction

Light weight insulation wallboard batten use fiber cement board or calcium silicate board production equipment and technology and inorganic insulation board production equipment,finish only one process,it is divided double layer panel and core material and no core material of the double panel battens,the core material is mainly composed of silicate cement and EPS foam and adhensive,fiber combinations.Its mainly used as interior wall partition and exterior wall substrate,instead of clay brick and color steel plate and other building materials,its a energy -saving innovations material, and its doesn’t need to re-surface material processing,you can use just surface treatment and decorative finishes paint.Sheet completely prefabricated in the factory according to GB8624-2006<building material and products combustion performance grading >standards,the combustion performance is class A1, thermal resistance to meet the building’s exterior wall system requirements. The product is no toxic, tasteless, non-polluting, moisture proof, fireproof,mildew-proof, mothproof, light weight, sound insulation, environmental protection, energy saving and insulation,construction easily and etc features of the new multi-purpose building materials.

2. Size:

Length: 1500-3000mm(usually 2270mm)

Width: 610mm

Thickness: 60/75/90/100/120/150/180mm

3. Advantage:

Sound-insulation

Best hanging force

Area –saving,fire-proof

Waterproof and damp proof

Anti-seismic and impact resistance

Largest Span and height thin webbed wall

Energy-saving, light weight, environment-friendly

Most civilized, healthy and high efficient construction

4. Application:

For interior and exterior wall partition on steel or concrete structure building, new construction or renovations. It can replace construction materials such as block, wire spatial grid structure perlite board, perlite porous board and etc. It can widely be applied to wall materials of various high and low buildings such as bank, office building, hospital, school, hotel, mall, amusement, old house reconstruction, residence and workshop.

5. Technology Index:

| Item | National Standards | Testing Indexes | |||||

| 60mm | 90mm | 120mm | 60mm | 90mm | 120mm | ||

| 1 | Anti-impact Capacity/times | ≥5 | ≥5 | ≥5 | ≥8 | ≥10 | ≥15 |

| 2 | Anti-bending damage load/times over deadweight | ≥1.5 | ≥1.5 | ≥1.5 | ≥3 | ≥4 | ≥5 |

| 3 | Compressive strength /Mpa | ≥3.5 | ≥3.5 | ≥3.5 | ≥5 | ≥5 | ≥5 |

| 4 | Softening coefficient | ≥0.80 | ≥0.80 | ≥0.80 | ≥1 | ≥1 | ≥1 |

| 5 | Surface density g/m2 | ≤70 | ≤90 | ≤110 | ≤55 | ≤70 | ≤85 |

| 6 | Moisture rate a/% | ≤12/10/8 | ≤10/9/7 | ||||

| 7 | Drying shrinkage value /mm/m | ≤0.6 | ≤0.6 | ≤0.6 | ≤0.45 | ≤.0.5 | ≤0.5 |

| 8 | Hanging Force/N | ≥1000 | ≥1000 | ≥1000 | ≥1200 | ≥1300 | ≥1500 |

| 9 | Sound insulation capacity in the air /Db | ≥30 | ≥35 | ≥40 | ≥35 | ≥40 | ≥45 |

| 10 | Fire proof limit /h | ≥1 | ≥1 | ≥1 | ≥2.5 | ≥3 | ≥4 |

| 11 | Heat transfer coefficient w/m2.k | ≤1.0 | ≤1.0 | ||||

| 12 | Radioactivity Limit | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 |

| 13 | IRa (Inner radiation indexes) | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 |

| 14 | Ir (Outer radiation indexes) | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 |